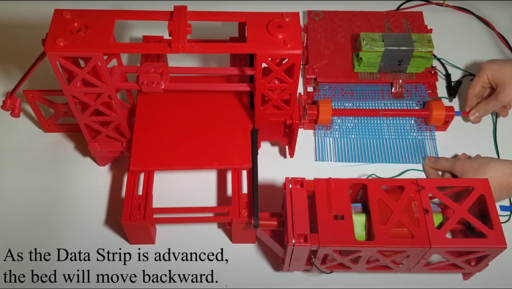

A 3D-printed data strip encodes instructions for the printer as holes in a plastic sheet, which open and close simple switches in the motor controller. These switches control the speed, direction, and duration of the motors’ movement, letting the data strip encode motion vectors.

LOL, he made a punch card controlled printer…that’s really awesome and fun use of old tech.

I don’t like purity for purity’s sake, but maybe at 545% tariffs, this starts to be an out.

3d printing lugs for carbon fiber, bamboo, metal tubes and beams, and fitting in regular motors, electronics, bearings, belts is a good/best path to reduced BOM and high performance/value.

Interesting, but not terribly useful unless you have a separate, likely electronics-driven, machine to punch plastic sheets for it (or have a pre-existing sheet defining something you want to replicate a bazillion of). It’s an ingenious but very niche machine.

Punch cards have been around for over 200 years. No electronics are needed to punch them. Some very complex patterns were created with the Jacquard loom without any computers. It just takes a massive amount of work to create the cards.

All technically true, but how many man-hours would it take to calculate the set of holes necessary to print each layer of a non-trivial object (say, a Benchy) without electronic assistance? I’m sure it could be done, but most people couldn’t do it in a practical timeframe. Taking presliced gcode and translating it via an automatic or even a manual system should be doable, but you still need a computer to slice the model into gcode.

Jacquard looms are a whole other crottle of greeps. Each warp position gets either raised or lowered, so it’s in essence a binary model rather than full analog—conceptually much simpler than this printer, whose punch language is going to have to include slots for longer motor moves. I’d guess that, in the old days, Jacquard patterns were set up for manual punching by drawing up a diagram (which would look like a piece of black-and-white pixel art) and transferring the information one row at a time to the punch. That doesn’t seem like it would work for this printer.